Repacking fee

The quantity you have requested will require us to break up a package. We charge a fixed fee for this per package.

Quantity can not be changed

Do you need more? Contact Customer service.

Kind on your floors – and on your ears

Vibration-welded felt pad on a sled base glide.

1. Do your components need felt pads?

We would be happy to help. We use a method called vibration welding, which requires the surface being felted to be flat.

As standard, we use felt discs of a diameter of 8mm and above, or alternatively felt squares. We can also use felt in custom shapes, for which we would need to develop a punching tool, which costs roughly 150 €.

Vibration welding is performed manually, and therefore costs roughly 0,2 - 0,3 £ per component.

In order to weld, we have to develop a bespoke felt welding tool for your specific component. This tool costs roughly 200 - 800 € .

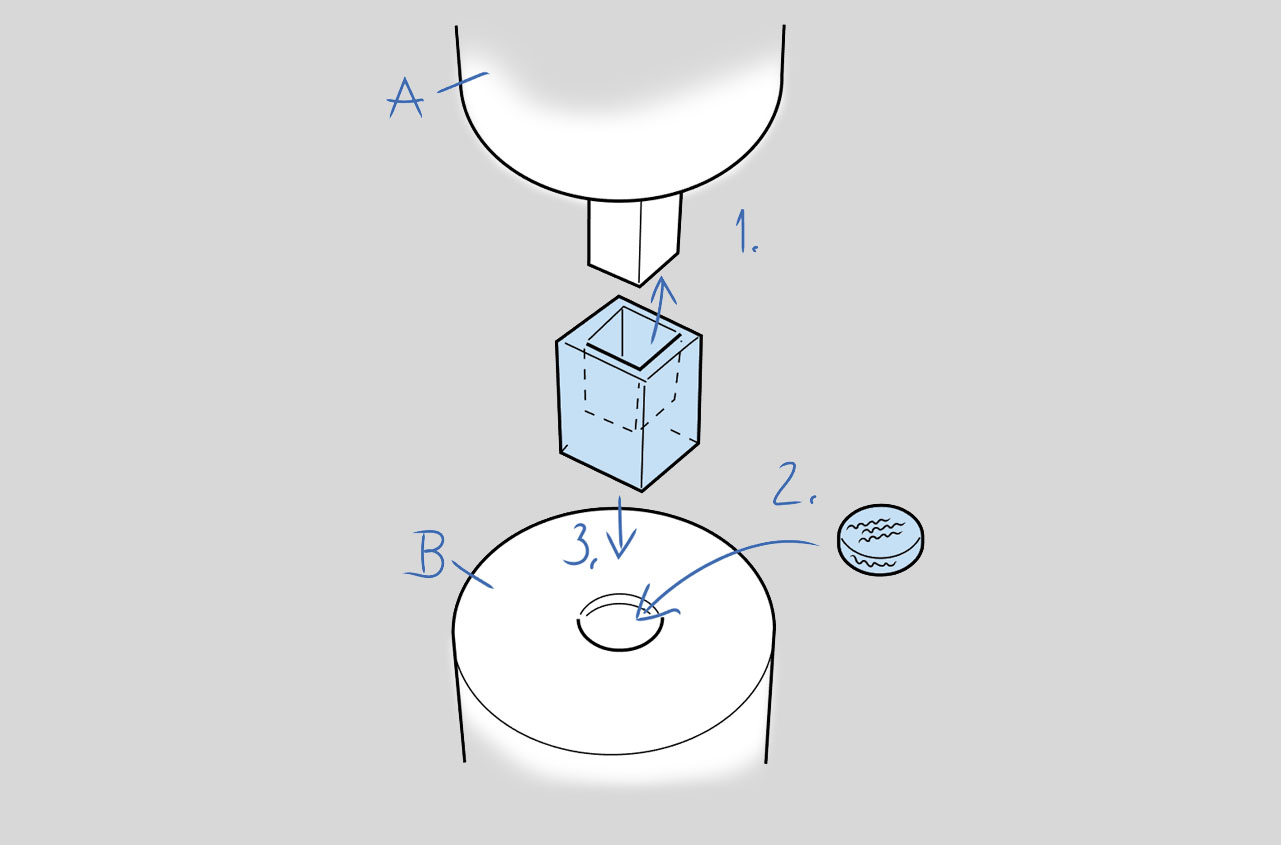

2. Vibration welding.

See the diagram below.

The felt welding tool – "A" and "B” – is fitted in the welding machine.

1. The component is manually fitted on the upper part of the tool.

2. The felt is placed on the lower part.

3. The component is pressed against the felt, simultaneously vibrating at high frequency until the surfaces are fused together.

3. Welded felt is very tough.

4. Who do you contact?

Always speak to one of our product specialists...this is where they are best. Find their contact details here>>