Repacking fee

The quantity you have requested will require us to break up a package. We charge a fixed fee for this per package.

Quantity can not be changed

Do you need more? Contact Customer service.

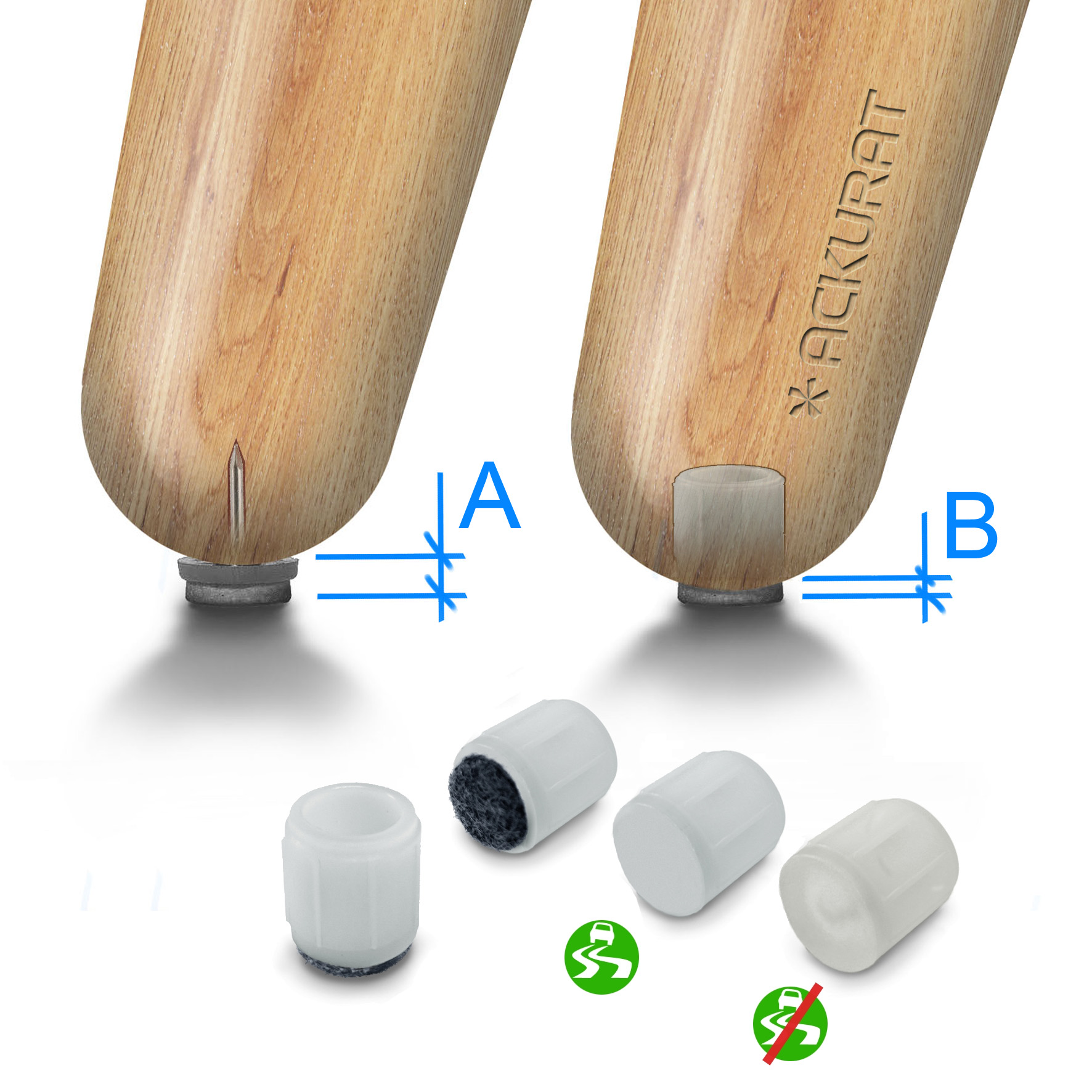

Nice legs ... all the way down

Do you ...

- design furniture legs in wood

- have thoughts on a round surface against the floor

- want to avoid the risk of nails and screws scratching the floor

- want a glide that feels like a natural part of the leg

- see bioplastics as a good alternative (some models)

This is how it works

1. Drill a hole

Where the leg meets the floor, you drill a hole 90 degrees from the floor. With the depth of the hole, you decide how much the foot will protrude.

2. Press on the glide

Press in the glide all the way in. Use a soft tool if neccessary.

Would you like more information?

Please, contact your Product Specialist. Here you find their contact details >

Range overview

Click on the link below the picture to get to the store.

The origin

As usual, this is about teamwork.

At a furniture fair in London, Claes Lindén (Ackurat) saw many stylish wooden furniture legs with rounded ends towards the floor. He then got the idea that it would be much nicer with an insert foot instead of a foot with a nail.

At home, Glenn Nilsson (Ackurat) took the project forward and designed products in different materials and designs.

Ines Zdenac (Ackurat) introduced additional variants with a round foot surface as an alternative for different slopes.

The tools was made by our knowledgeable tool makers in our own tool workshop.