Repacking fee

The quantity you have requested will require us to break up a package. We charge a fixed fee for this per package.

Quantity can not be changed

Do you need more? Contact Customer service.

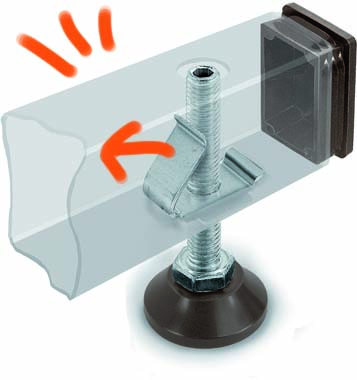

Just press in and screw

Do you...

- manufacture shop shelving or POP displayes

- want to avoid threading

- want less masking before painting.

This is how it works

1. Make a hole

Punch a hole. The foot needs 30 x 15 mm. Keep in mind that coating may reduce the hole a little bit.

2. Press in

Hook in the foot on the side that's opposite the long "wing".

3. Fasten the foot

Screw in the adjustable foot so far that the foot is fasten when you pull it.

Adjustment of height is then made when the furniture is in place.

You can order here

Would you like more information?

Please, contact your Product Specialist. Here you find their contact details >

The origin

As usual, this is about teamwork.

During a customer visit by Fredric Fagerberg (Ackurat), the customer showed a foot with bracket for the end of vertical profiles and tubes. The advantage was that you did not have to weld and thread. The customer wanted us to take the idea further and develop a standard range.

Claes Lindén (Ackurat) then made a similar concept for horizontal tubes.

Jim Wilhemsson (Nufotec) then developed the final product.